what kind of pump do i need to create a vacuum chamber

Vacuum Pumps

Introduction

This article gives manufacture insights into vacuum systems and vacuum pumps. Read further to learn more than.

- Vacuum pump overview

- Vacuum ranges

- Types of vacuum pumps and their operating principles

- Difference betwixt wet and dry lubrication

- And much more than…

Chapter 1: What is a Vacuum Pump?

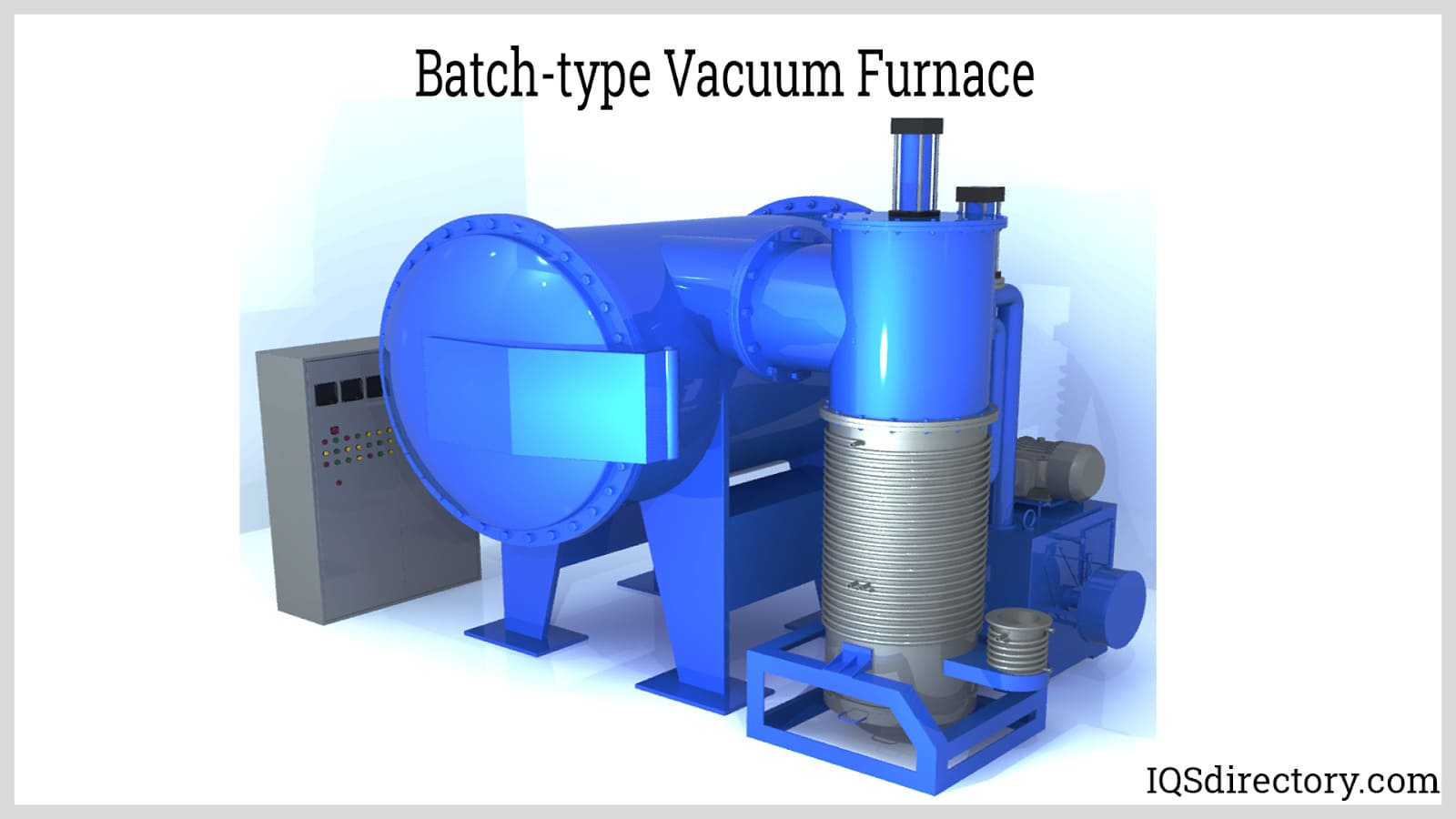

A vacuum pump is a slice of equipment capable of generating a partial vacuum or a low-pressure space by drawing gas molecules out of a sealed sleeping room. A vacuum is a relative state at which the chamber pressure has a lower pressure level than the ambience atmosphere or adjacent systems. Note that this is different from accented vacuum in which the force per unit area is at 0 Pa accented and is completely devoid of gas molecules. There are different degrees of vacuum that can exist created. It can range from beingness a low vacuum with an accented pressure range of 1 to 0.03 confined to an extremely loftier vacuum with a pressure of a billionth of a Pascal. Depression and medium vacuum are commonly seen in industrial systems such as vacuum grippers, vacuum cleaners, incandescent bulbs, painting, sandblasting, vacuum furnaces, and negative pressure ventilation. Higher vacuum systems are used for laboratory applications such as particle reactors and accelerators.

There are 2 master categories of generating partial vacuum. One is by gas transfer or gas feeding and the other is through entrapment. Gas transfer types of vacuum pumps piece of work by mechanically removing gases through positive displacement or momentum transfer. Positive deportation vacuum pumps take chambers that alternately aggrandize and contract with check or non-render valves to draw and eject menses. Momentum transfer pumps work by accelerating gases creating a low-pressure level region in its wake. Entrapment vacuum pumps, on the other hand, capture gas molecules past various principles such as condensation, sublimation, adsorption, ionization, and so on.

Chapter two: Vacuum Ranges

Vacuum ranges or regimes are classifications of the quality of vacuum characterized by the measurement of the absolute pressure level of the system. The accented force per unit area represents the amount of remaining affair inside the arrangement, mostly composed of gas molecules such as nitrogen, oxygen, h2o vapor, and trace gases such as neon, helium, and hydrogen.

Dissimilar vacuum ranges crave different pumping techniques. Low and medium vacuum ranges tin exist achieved past positive displacement vacuum pumps. These are suited for nearly industrial systems. Achieving loftier and ultra-loftier vacuum ranges for special applications such equally surface analytic techniques, microscopy, and nanolithography are achieved by both momentum transfer and entrapment pumps.

| Vacuum Range | Accented Pressure (Pa) |

|---|---|

| Atmospheric | 101,325 |

| Low Vacuum (Rough, Coarse) | ane.01 x 10⁵ to 3.33 10 x³ |

| Medium Vacuum | three.33 x 10³ to 1 x x⁻¹ |

| High Vacuum | ane x 10⁻¹ to 1x10⁻⁷ |

| Ultra-high Vacuum | i x 10⁻⁷ to 1 x 10⁻¹⁰ |

GET YOUR COMPANY LISTED Below

Leading Manufacturers and Suppliers

Chapter 3: Types of Vacuum Pumps and Their Operating Principles

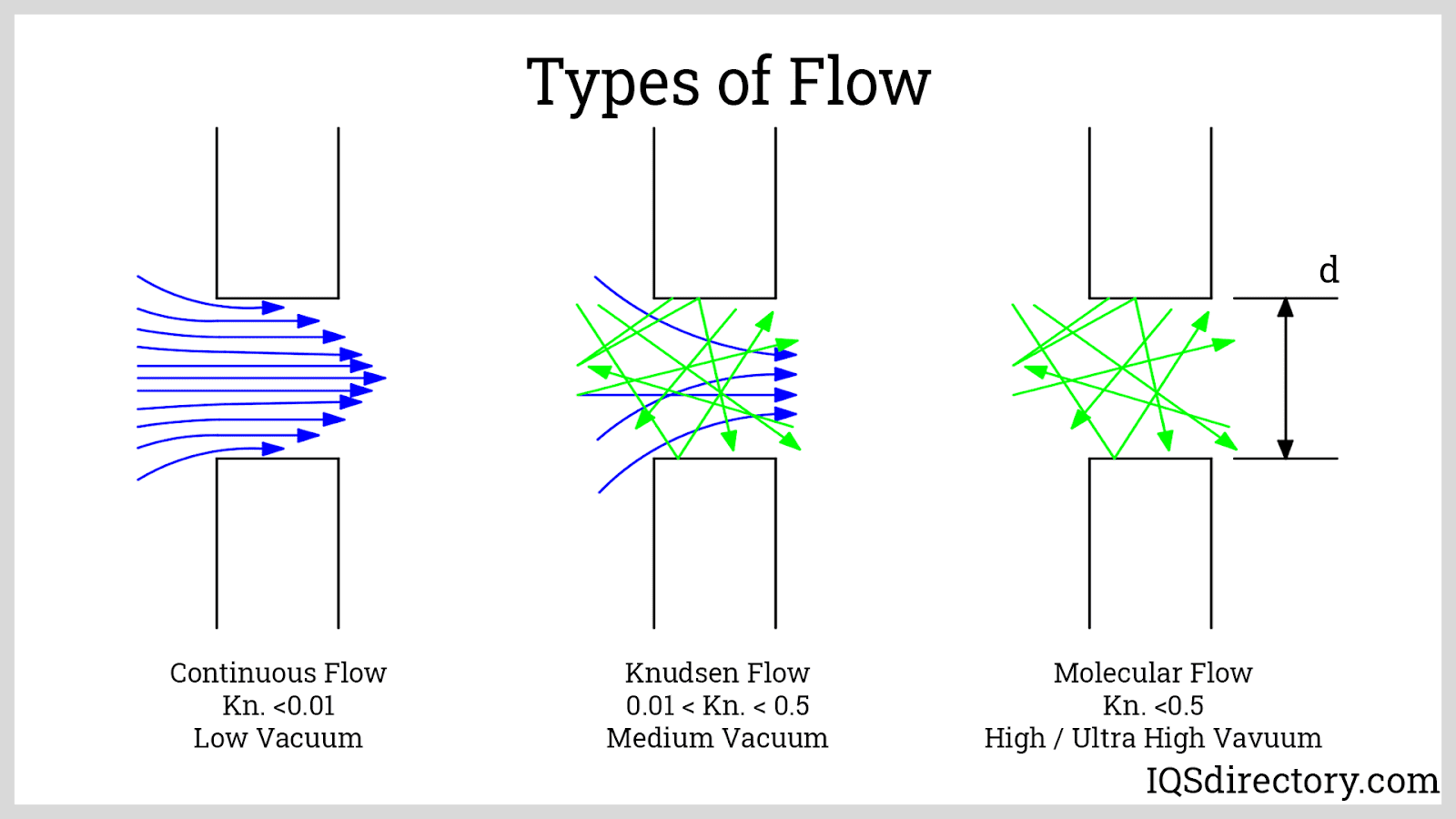

The two main classifications of vacuum pumping principles are gas transfer and entrapment. Gas transfer is farther divided into positive displacement and momentum transfer. To further grasp the concepts of vacuum pumps, it is best to sympathise the iii types of flow: viscous, transitional, and molecular. Glutinous or continuous flow occurs at high pressures to medium vacuum. In this type of menstruation, the gas is dumbo enough for gas molecules to collide with each other. The mean free path or the average distance traveled by a gas molecule is less than the dimensions of the bedroom. When a higher vacuum is reached, the gas molecules tend to collide on the walls of the chamber more than other gas molecules. Transitional catamenia occurs when the pasty flow starts to alter into molecular flow. Molecular catamenia is characterized by the random motion of gases where their mean free path is much longer than the dimensions of the chamber.

Fluids flowing nether gummy menses tin be pumped mechanically by positive displacement pumps. However, molecular flow will be reached when the gas cannot be evacuated past pressure level divergence. At this point, another pumping system, either momentum transfer or entrapment, is used. Most high vacuum systems accept 2 pumps in tandem. Positive deportation pumps alone are not sufficient at higher vacuum. Momentum transfer pumps will stall if the system when operated at gluey flow. Entrapment pumps will be frequently regenerated or exhausted when in that location is too much gas to be captured particularly at viscous menstruation.

Positive Displacement Vacuum Pumps

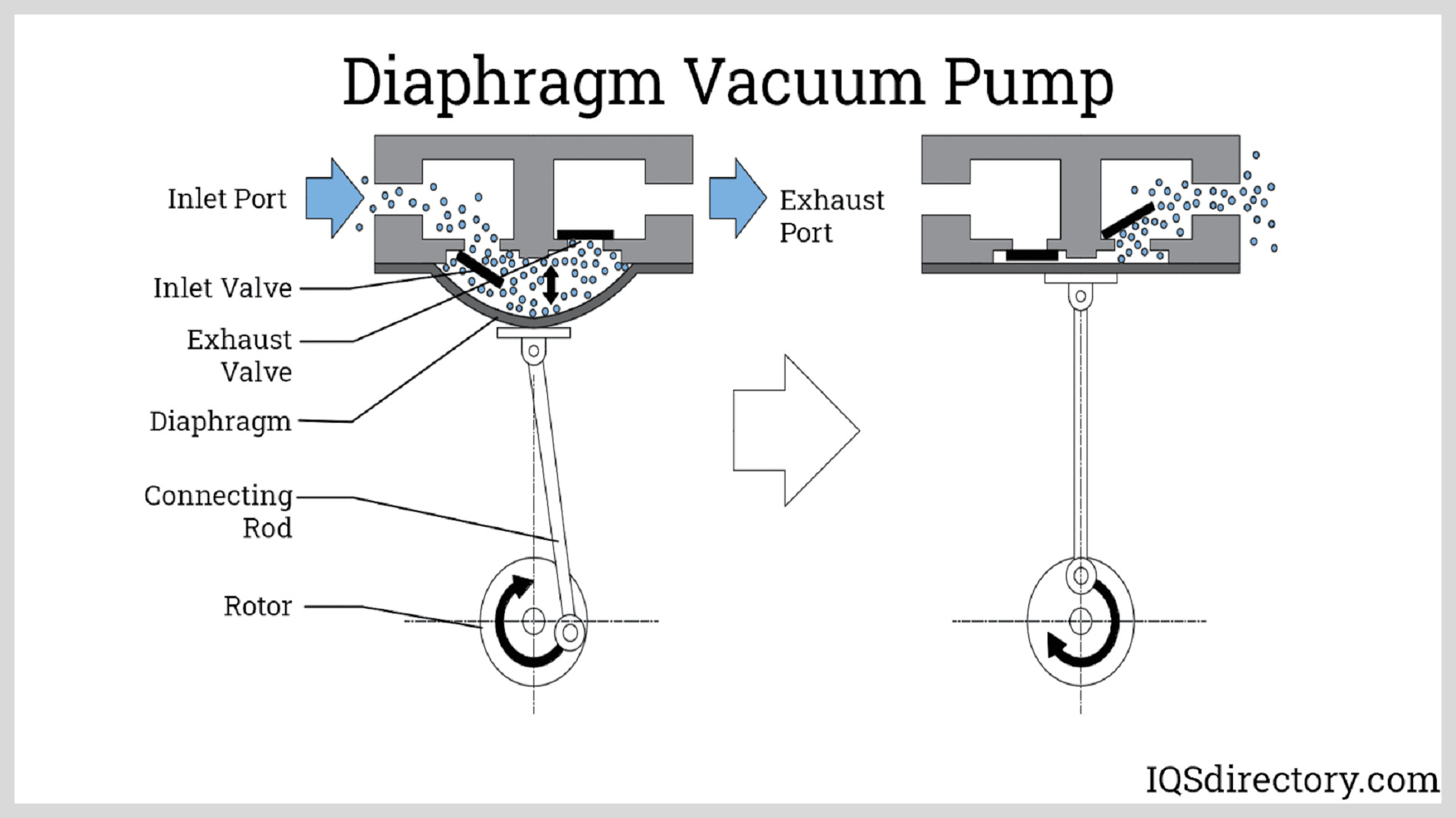

Positive deportation vacuum pumps operate by expanding and contracting a sealed sleeping accommodation where the flow of fluid is controlled by 1-way valves. The vacuum generation procedure starts by expanding a sealed chamber generating a vacuum. This vacuum draws the fluid into the chamber through an intake valve. Upon reaching the maximum expansion, the intake valve closes while the exhaust opens. The fluid is ejected out of the sleeping room as information technology compresses or contracts. The wheel repeats several times per 2d itself creating a pulsating catamenia.

Like ordinary pumps, positive deportation vacuum pumps are classified according to the movement and the pattern of the chamber. There are two main categories: reciprocating and rotary.

- Reciprocating Vacuum Pumps: These types of pumps have chambers that expand and contract through the reciprocating or repetitive back-and-forth motion. The range of motion of the moving component is called a stroke. Reciprocating pumps have two one-way ports or valves, i for the inlet and the other for the exhaust. The alternate opening and endmost of these valves allow the build-up of vacuum and ejection of the fluid. The three chief types of reciprocating vacuum pumps are piston, plunger, and diaphragm vacuum pumps.

- Reciprocating Piston Vacuum Pump: This type of pump generates vacuum and pinch through the movement of the piston sealed against a cylinder. The piston is connected to the crankshaft via a connecting rod. As the crankshaft rotates, the piston is pushed back-and-forth inside the cylinder. The pistons are ordinarily made of cast iron, bronze, or steel.

- Plunger Vacuum Pump: This type of pump operates the aforementioned way equally a reciprocating piston pump. The piston or plunger of this pump is a long, solid cylinder typically fabricated of difficult-coated ceramic. The long profile of the plunger allows the high-pressure seal to be stationary relative to the cylinder, in contrast with piston pumps where the seal is attached to the piston. This enables the employ of more complex sealing systems. Plunger vacuum pumps are more than suited for more than demanding conditions than piston vacuum pumps.

- Diaphragm Vacuum Pump: Diaphragm vacuum pumps use a deformable metallic or elastomer membrane permanently joined into the bedroom creating a hermetic seal. Piston vacuum pumps accept the advantage when it comes to reliability and power, while diaphragm vacuum pumps are more often than not suited for ejecting hazardous or corrosive substances.

- Reciprocating Piston Vacuum Pump: This type of pump generates vacuum and pinch through the movement of the piston sealed against a cylinder. The piston is connected to the crankshaft via a connecting rod. As the crankshaft rotates, the piston is pushed back-and-forth inside the cylinder. The pistons are ordinarily made of cast iron, bronze, or steel.

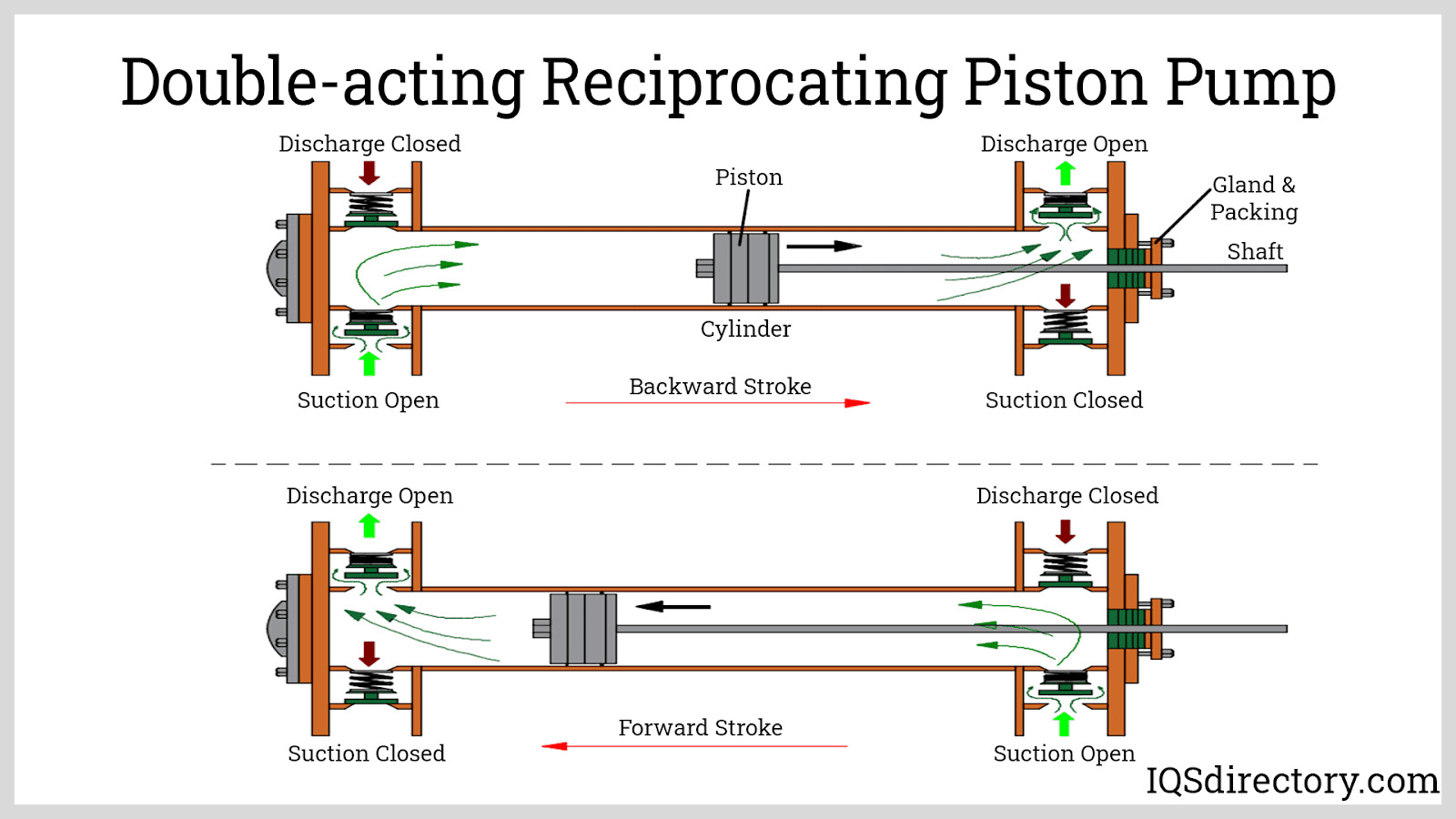

Reciprocating vacuum pumps can likewise be classified according to the number of the chambers mainly to address the problem of pulsating flow. A pulsating menstruum is an undesirable characteristic of reciprocating pumps where the flow is delivered in short bursts. Adding more pistons and cylinders will create a more abiding flow. This brought the development of reciprocating pumps with multiple piston-cylinder assemblies known as multiplex pumps.

In terms of the achieved cycle phase per stroke, reciprocating pumps are categorized as either unmarried- or double-acting. Single-acting pumps create only either vacuum or pinch in a single stroke. In this configuration, the piston or diaphragm is coupled to only ane sleeping accommodation where only one side engages the fluid. A double-interim pump, by contrast, creates both vacuum and compression in a single stroke. A common configuration is a twin piston-cylinder or twin diaphragm assembly which is actuated past a single bulldoze rod. Other designs can characteristic a unmarried piston or diaphragm serving two chambers. Double-acting pumps are more commonly used due to ameliorate efficiency, higher flow charge per unit, and less pulsating flow.

- Rotary Vacuum Pumps: As the name suggests, these types of vacuum pumps create depression-pressure regions through the rotation of the moving components against the pump housing. The mating surfaces betwixt the rotor and the housing accept very pocket-size clearances coated with cocky-lubricating or depression friction materials such as graphite, PTFE (polytetrafluoroethylene), or PEEK (polyether ether ketone). The small clearance prevents the fluid from leaking to the depression-pressure side. In comparing with reciprocating types, rotary vacuum pumps accept lower pulsating commitment making the flow more continuous. Withal, they are non suited to handle fluids contaminated past abrasive media since it tin erode the small clearances between the rotor and the housing. Rotary vacuum pumps are classified according to the pattern of the rotor.

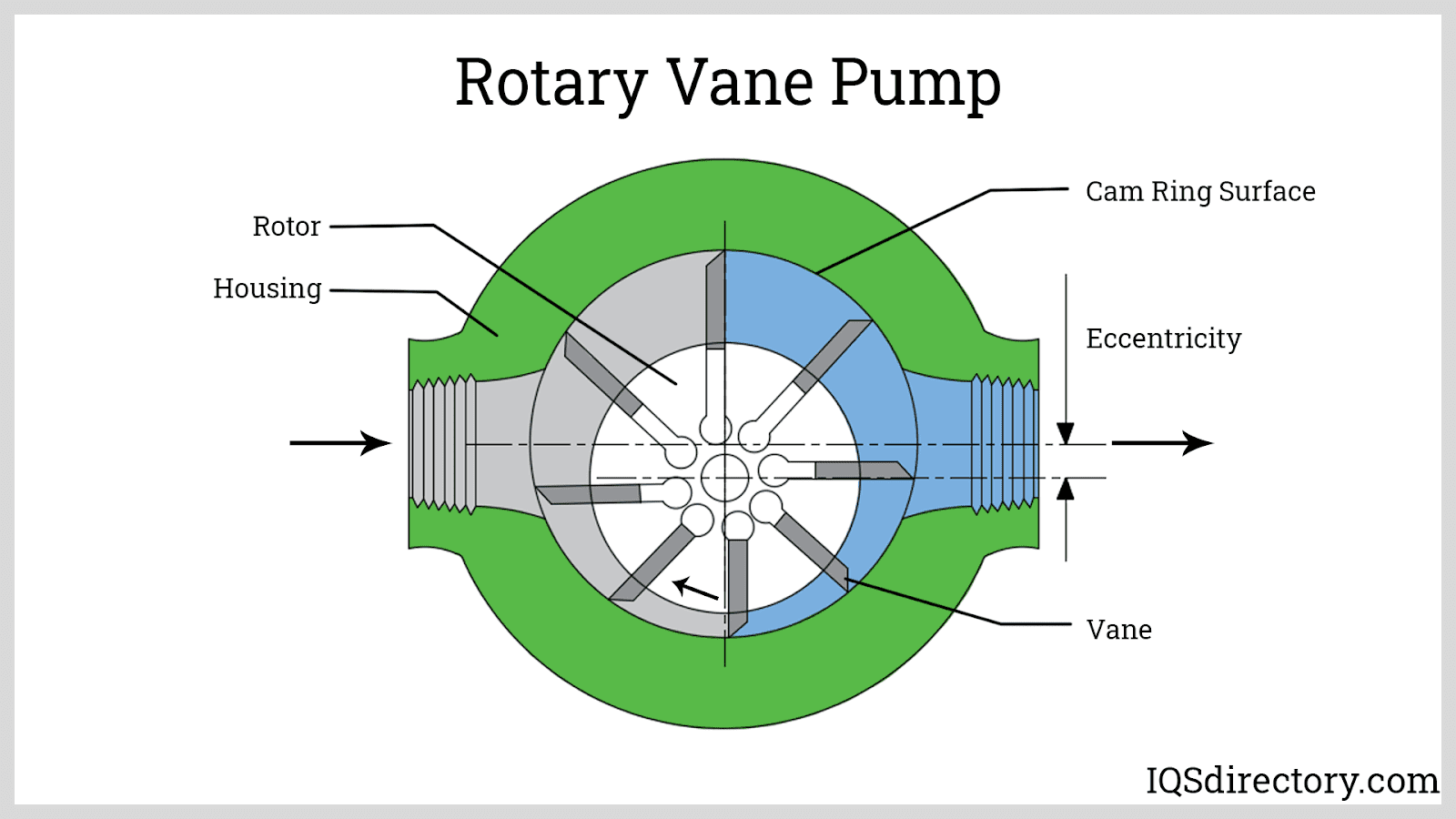

- Rotary Vane Vacuum Pump: Rotary vane vacuum pumps are the about common type of positive displacement vacuum pump. This pump has vanes inserted radially into a circular rotor. The rotor is eccentrically installed relative to the stator housing. This eccentricity is known as the stroke of the pump. The individual chambers separated past the vanes progressively become smaller as it approaches the discharge. The vanes are allowed to motion radially which press confronting the housing mainly through the centrifugal force as the rotor rotates. A bound energizes the vanes or holds the vanes in place when the rotor is non in motion.

- Liquid Band Vacuum Pump: Liquid ring pumps operate similarly to rotary vane pumps but have different vane construction. As mentioned earlier, rotary vane pumps have vanes that are free to movement radially. The vanes of a liquid ring vacuum pump, however, are fixed to the rotor. When the rotor rotates, the liquid is drawn into the chamber by the expansion of cavities due to the eccentricity of the rotor. Centrifugal forces hold the liquid confronting the housing forming a ring of liquid, hence the name.

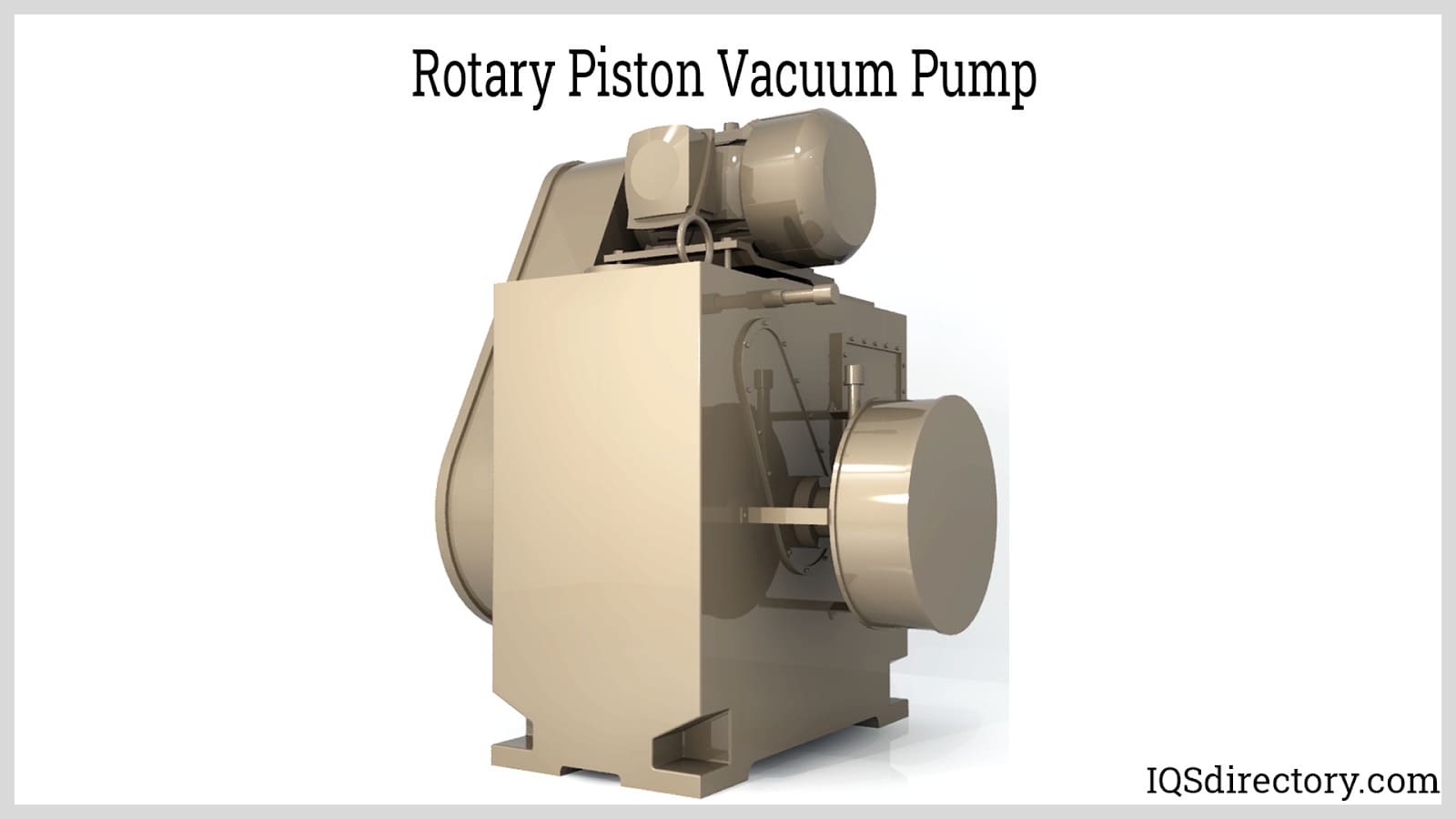

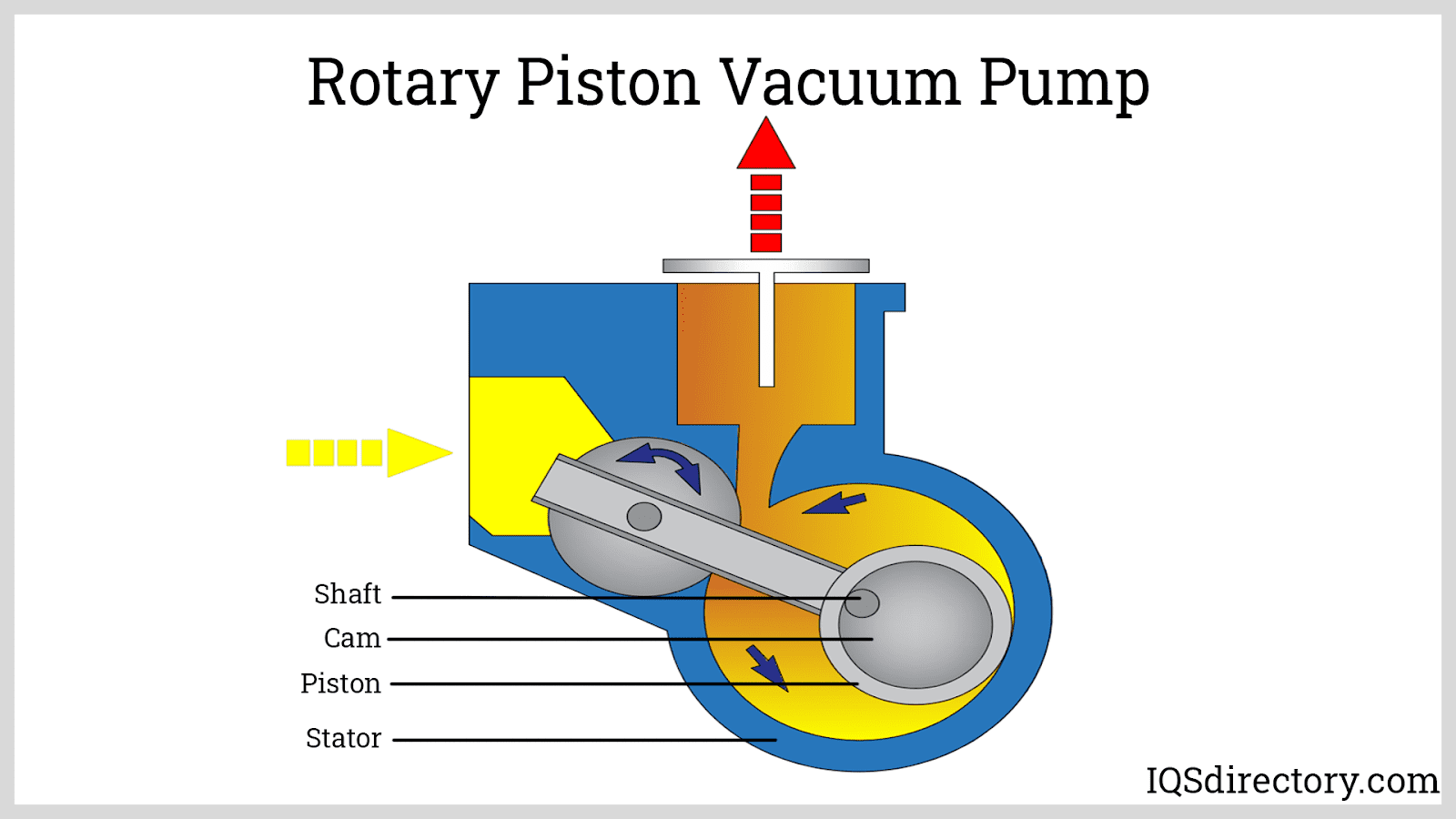

- Rotary Piston Vacuum Pump: A rotary piston vacuum pump has an eccentric wheel equally the rotor which is fastened to a slide valve. Rotary piston valves can exist considered as two-stroke, double-acting pumps with two separate compression chambers. As the bike rotates during the intake stroke at the get-go chamber, the slide valve opens assuasive the entry of the fluid. Opposite this chamber is another that undergoes an exhaust stroke. This 2nd chamber has an exhaust valve where the compressed fluid is ejected. Like the rotary vane, the pinch chamber is created by mating the rotor, in this case, the eccentric wheel, against the pump housing. This bedroom progressively becomes smaller at the end of the frazzle stroke.

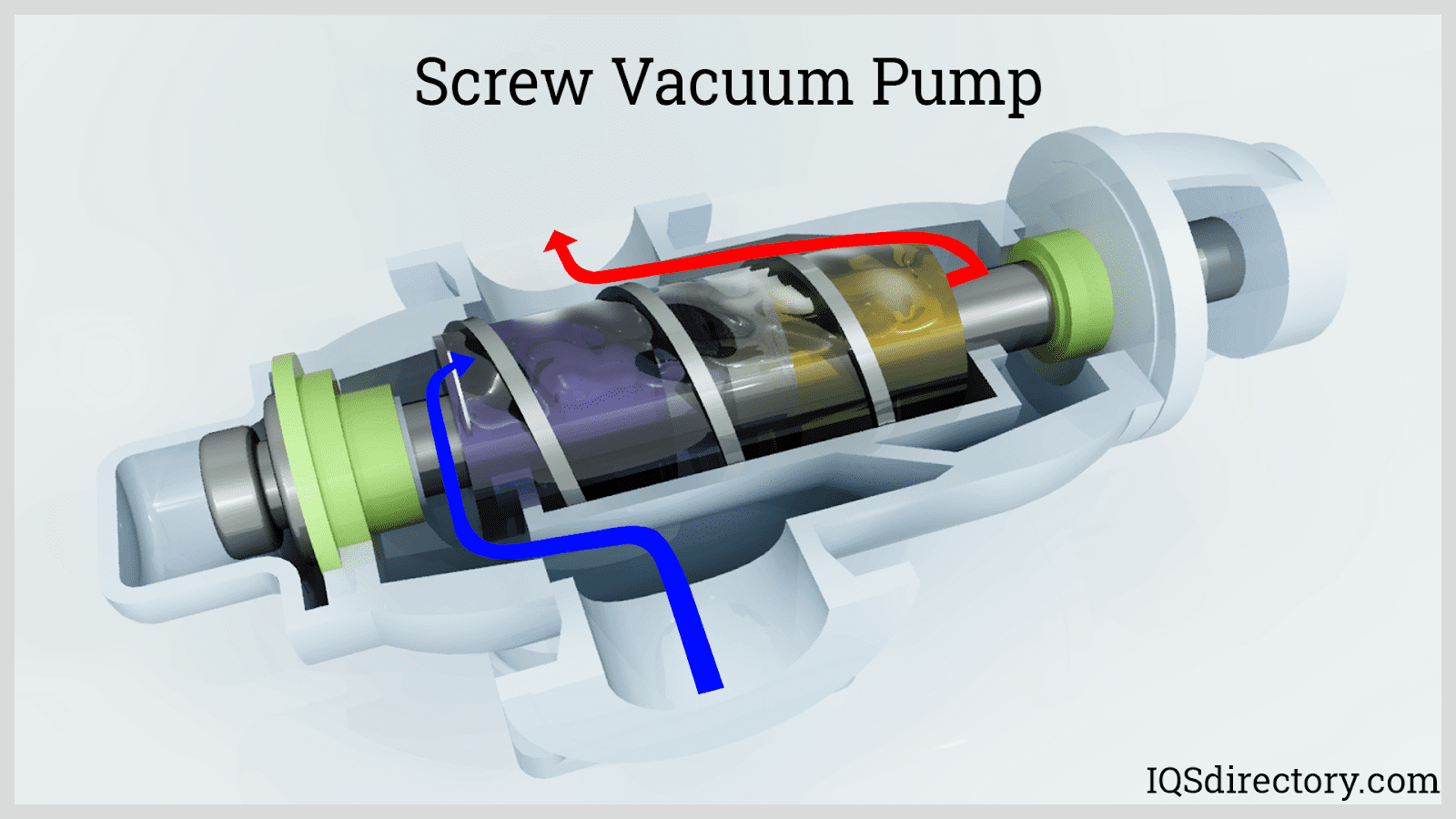

- Screw Vacuum Pump: A rotary spiral pump is ane of the earliest developed positive displacement pumps which was known as the Archimedes' screw. In its simplest form, this pump consists of a single screw inside a hollow cylinder. Modern designs incorporate double or triple screws meshing against each other. As the fluid enters the pump, it becomes trapped in the cavities between the threads of the screw and the housing. The force per unit area is developed by the rotation of the screw ejecting the fluid on the other side. It is suitable in handling unmarried and multiphase fluids and has higher tolerance in handling fluids with annoying contaminants.

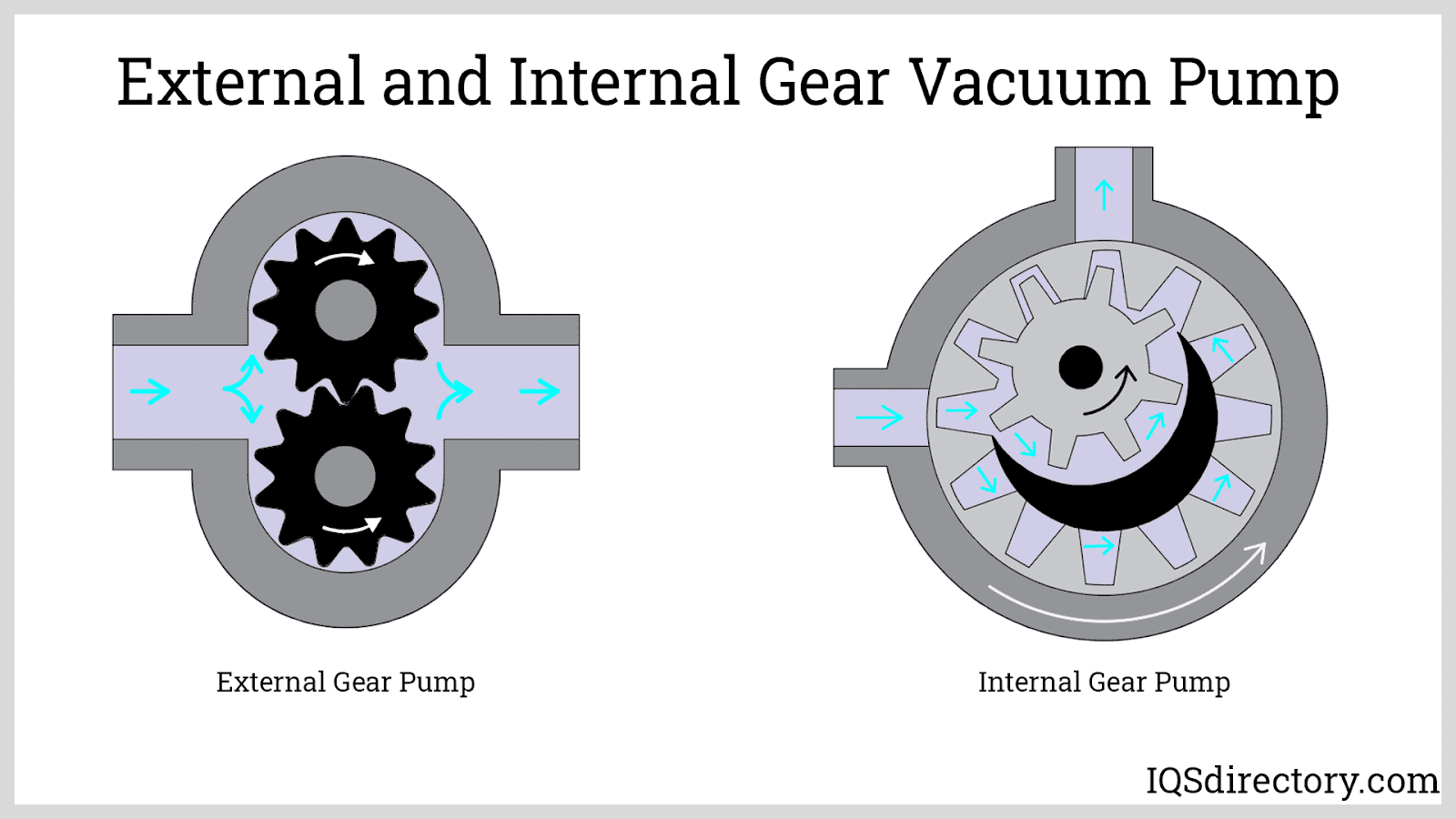

- Gear Vacuum Pump: This type of reciprocating pump has rotors in the form of two meshing gears where one gear drives the other. Gear pumps tin be either external or internal. An external gear pump has two mating external gears. External gear pumps operate by creating an expanded cavity every bit the teeth come out of mesh when rotating towards the inlet. The fluid is drawn into this crenel due to the vacuum generated. As the gears rotate, fluid is trapped betwixt the teeth and the pump housing. The fluid is ejected to the other side of the chamber. On the other hand, internal gear pumps take rotors composed of a driven external gear and an internal gear. Pumping is achieved the same fashion as external gear pumps where the fluid is drawn from the expanding crenel equally the gear teeth come out of mesh.

- Lobe (Roots) Vacuum Pump: Lobe vacuum pumps deliver fluid the same way equally gear pumps. But instead of having mating gear teeth, lobe pumps have two or more meshing lobes. These 2-lobe rotors are both driven and timed with one another. This allows the rotors to rotate with no contact. Thus, loftier rotating speeds are possible with less clothing to the rotor. This feature of timed rotation is available in gear pumps as well. Moreover, the lobes also allow a continuous fluid seal contact across the surfaces of the lobes. Gear pumps have a fluid seal that jumps discontinuously from teeth to teeth.

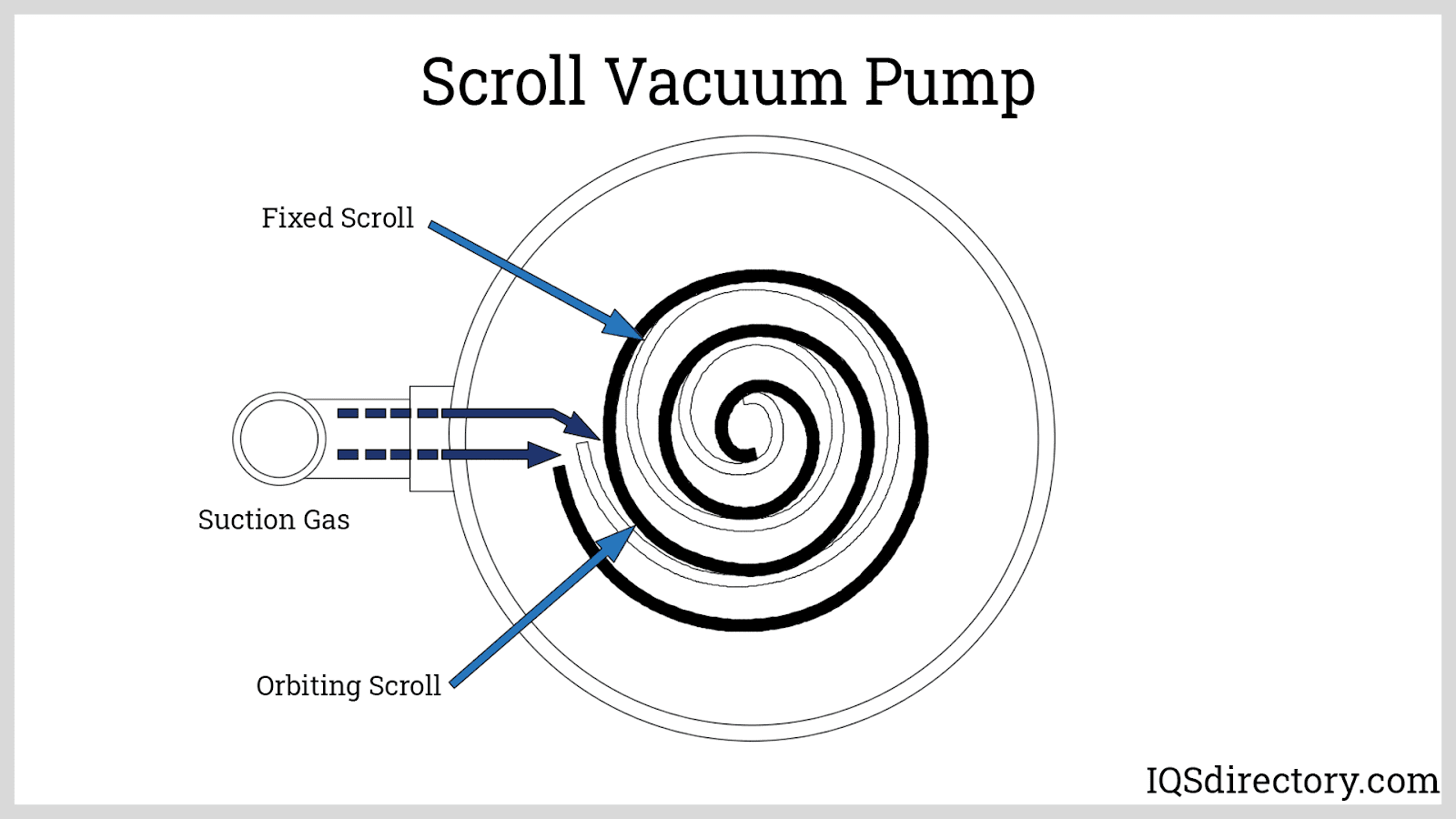

- Curl Vacuum Pump: This blazon of pump is composed of two co-wound spirals or scrolls with i interim every bit the rotor while the other as a stator. The rotor does not rotate merely moves eccentrically relative to the other. Whorl pump works by cartoon fluid from the periphery of the scrolls. The fluid trapped between the scrolls is transported towards the center where the volume is progressively decreased.

- Rotary Vane Vacuum Pump: Rotary vane vacuum pumps are the about common type of positive displacement vacuum pump. This pump has vanes inserted radially into a circular rotor. The rotor is eccentrically installed relative to the stator housing. This eccentricity is known as the stroke of the pump. The individual chambers separated past the vanes progressively become smaller as it approaches the discharge. The vanes are allowed to motion radially which press confronting the housing mainly through the centrifugal force as the rotor rotates. A bound energizes the vanes or holds the vanes in place when the rotor is non in motion.

Momentum Transfer Pumps

Momentum transfer pumps operate by inducing the motility of gas or liquid molecules through kinetic free energy transfer. This happens at the molecular period, in contrast to the viscous or continuous flow occurring in positive displacement pumps. The uniform velocity distribution of the molecules is altered continuously to a preferred management by the fast-moving surfaces hitting them. These surfaces are non but limited to impeller surfaces, but to other liquids besides. An case is a diffusion pump where high-speed jets of motive fluid impart momentum to the gases to be drawn from the inlet. Momentum transfer pumps are suited for creating a high vacuum. However, to create a molecular flow, low pressure must exist throughout the organization. The exhaust cannot be directly released to the atmosphere or at pressures where backstreaming can occur. To solve this problem, a backing pump is installed in tandem with the vacuum pump. The bankroll pump can exist a positive displacement pump that operates at a lower vacuum level which can directly discharge to the temper.

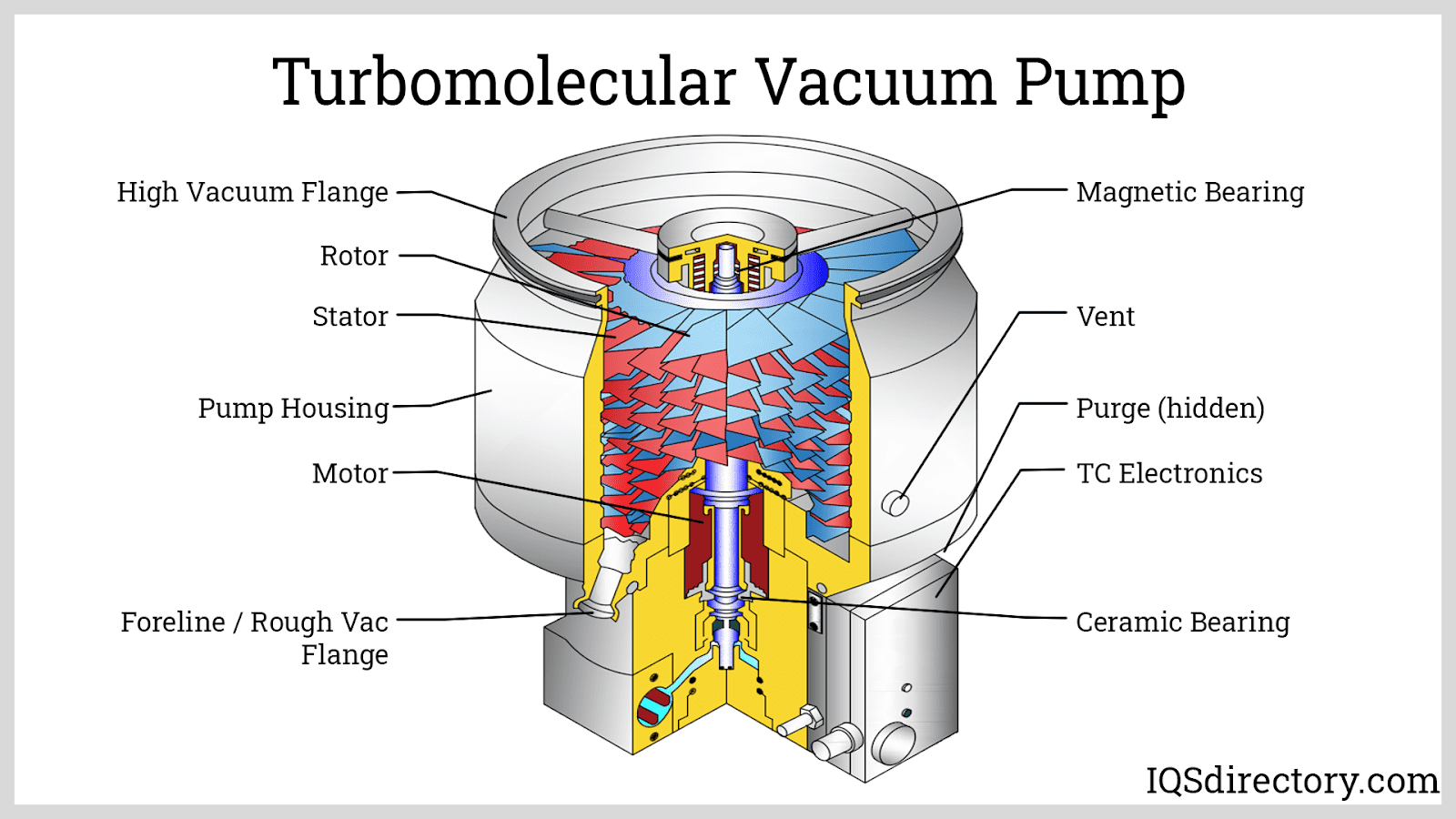

- Turbomolecular Vacuum Pump: A turbomolecular vacuum pump has multiple stages of rotating and stationary turbine blades. The rotating blades are angled in such a way that it transfers sufficient momentum to the gas molecules moving them axially towards the subsequent stages until information technology reaches the frazzle. The stator has angled blades as well and ensures the correct management of the gas. Since the mass of the gas is very small, the rotors must rotate at very high speeds. Friction heat build-upwards and rotor deflection limit the pattern of turbomolecular pumps.

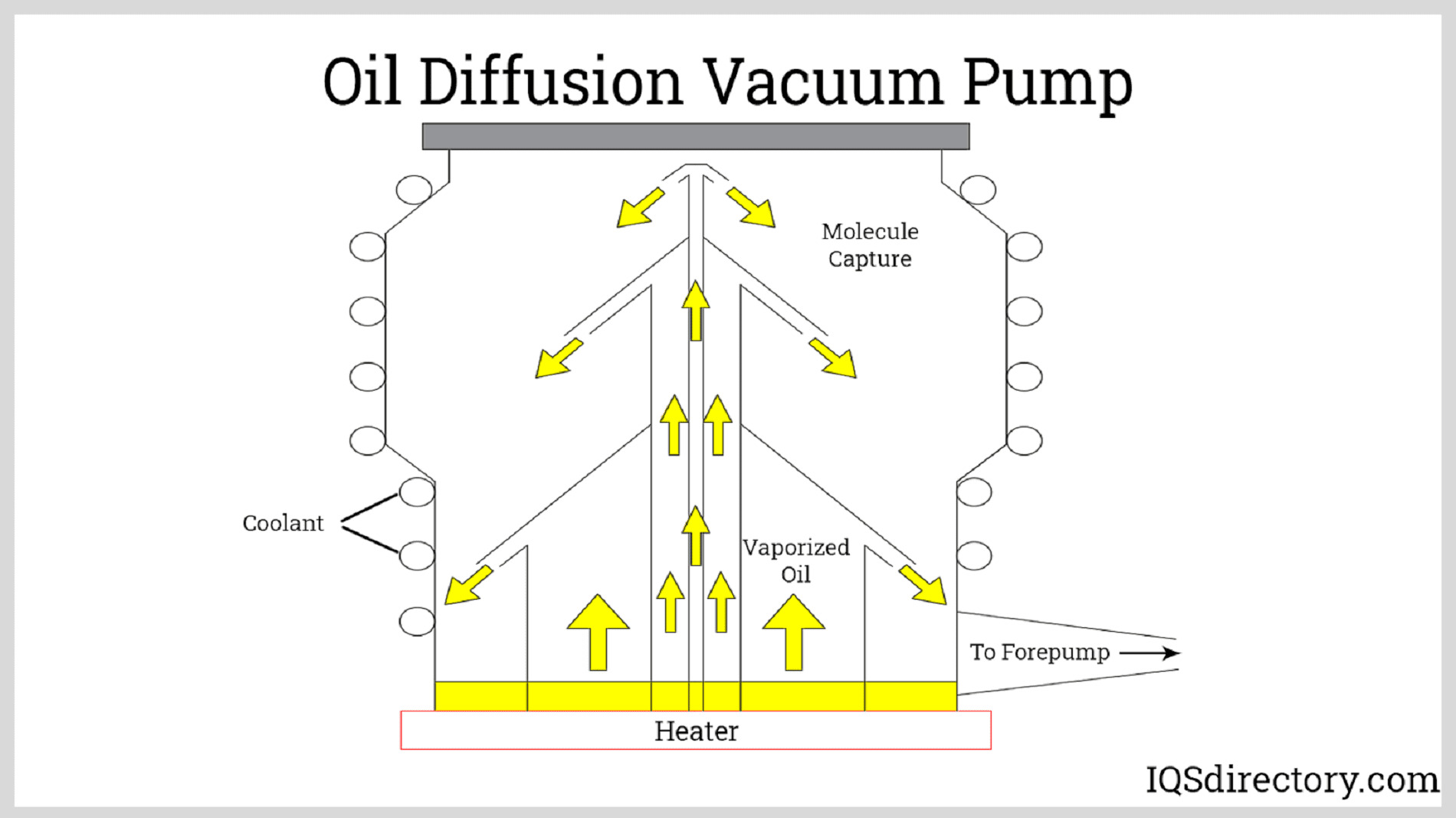

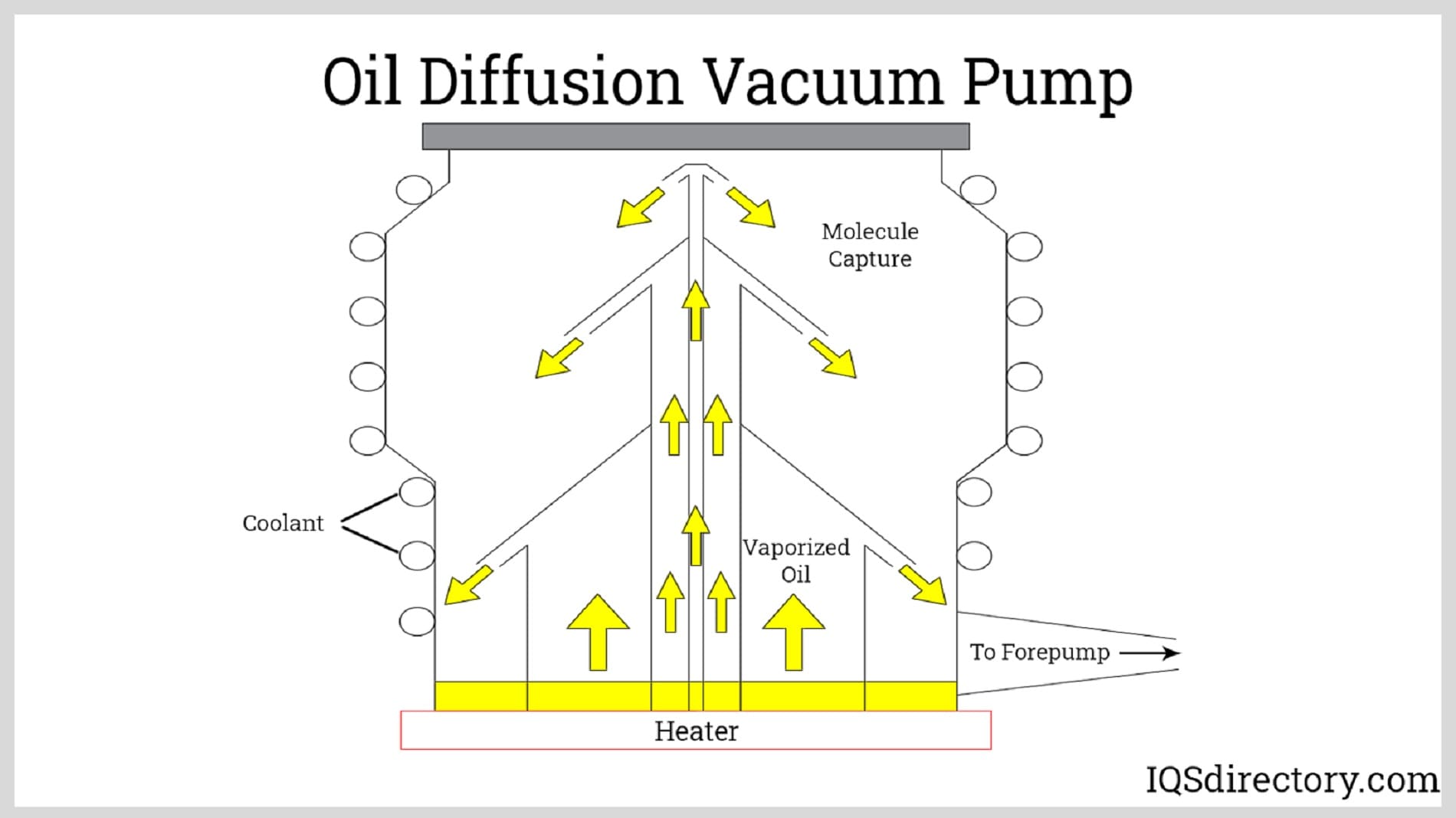

- Diffusion Vacuum Pump: As mentioned earlier, a diffusion pump works past using a motive fluid used to transfer momentum to the gas molecules. The motive fluid is usually oil or steam. The general design of an oil diffusion pump involves a heater to rut the oil and is ejected to nozzles on top of the boiler or vaporizing chamber. The vaporized oil leaves the nozzles at supersonic speeds which collects randomly flowing gases drawn from the low-force per unit area bedroom. Cooling coils are nowadays to condense the vaporized oil which and then returns to the boiler. The collected gas molecules continue to flow towards the exhaust. Steam or hydrocarbon gas ejectors work similarly. But these types do non need a boiler since the steam or motive fluid is already vaporized and has sufficient speed.

Entrapment Vacuum Pumps

Entrapment vacuum pumps employ multiple concrete and chemical phenomena to capture gas molecules. The working principle is different from each type. Common to well-nigh all entrapment pumps is their power to operate at high vacuum regimes without whatever oil contamination. Entrapment vacuum pumps do not rely on rotors or other moving parts. The downside, however, is that it cannot operate continuously since information technology needs to exist regenerated once the surface or material capturing the gases is total. Moreover, they cannot remove lighter gases such as hydrogen, helium, and neon. Below are some of the common entrapment vacuum pumps.

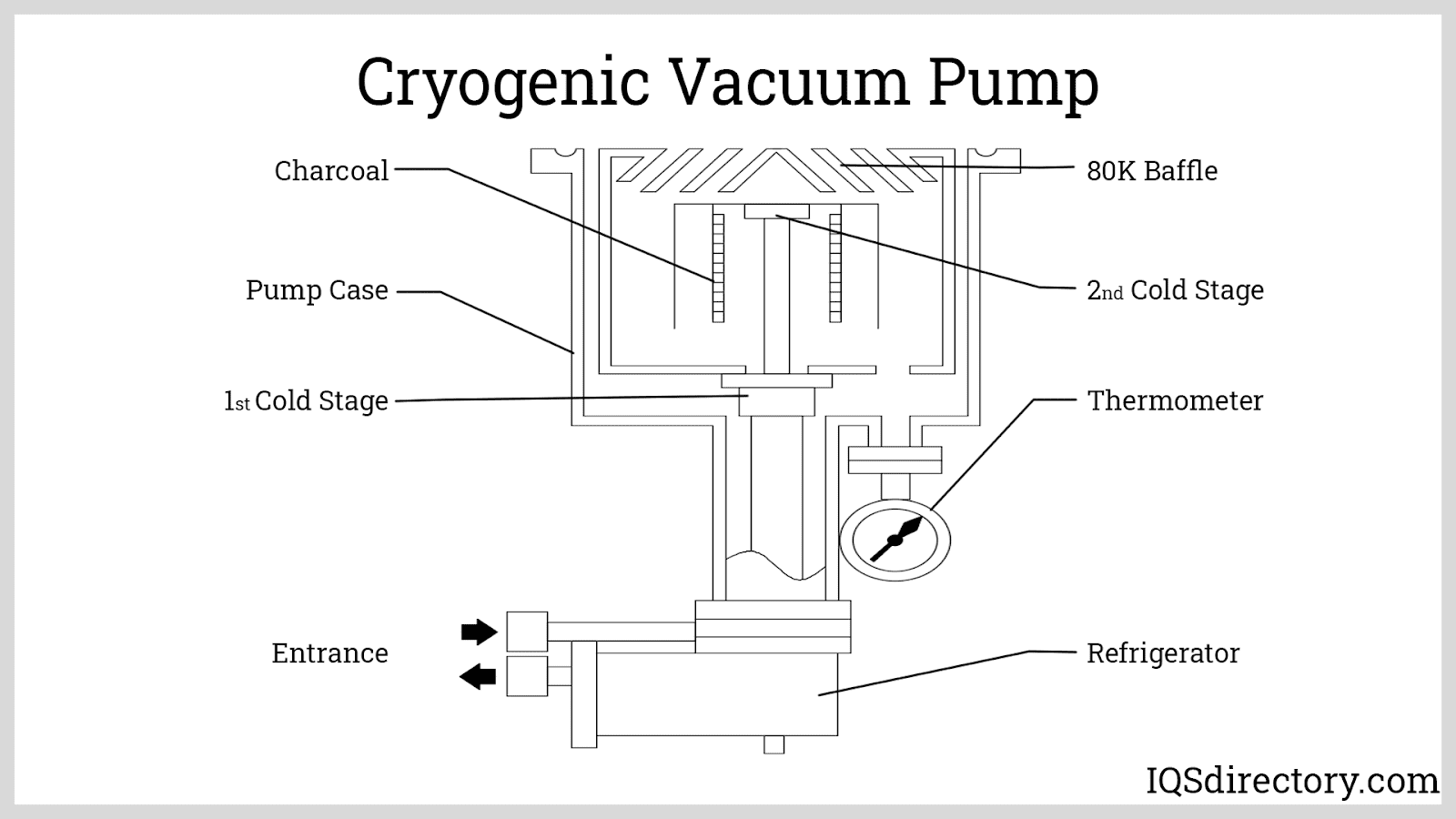

- Cryogenic Vacuum Pump: This type of vacuum pump works by cooling the gas downwards to its condensation or freezing point. Information technology captures gases such equally nitrogen and oxygen below twenty Yard at the high vacuum regime. For capturing lighter gases such as helium and hydrogen, they must be cooled down to 8 to 10 Grand. The typical design of a cryogenic pump is a 2-stage libation. The kickoff stage is for removing water vapor and oil by cooling at around 70 to eighty One thousand. The second stage is for removing gases that absurd at around 10 to twenty K. At this stage, an adsorbent such as activated charcoal is integrated to capture the cooled gases.

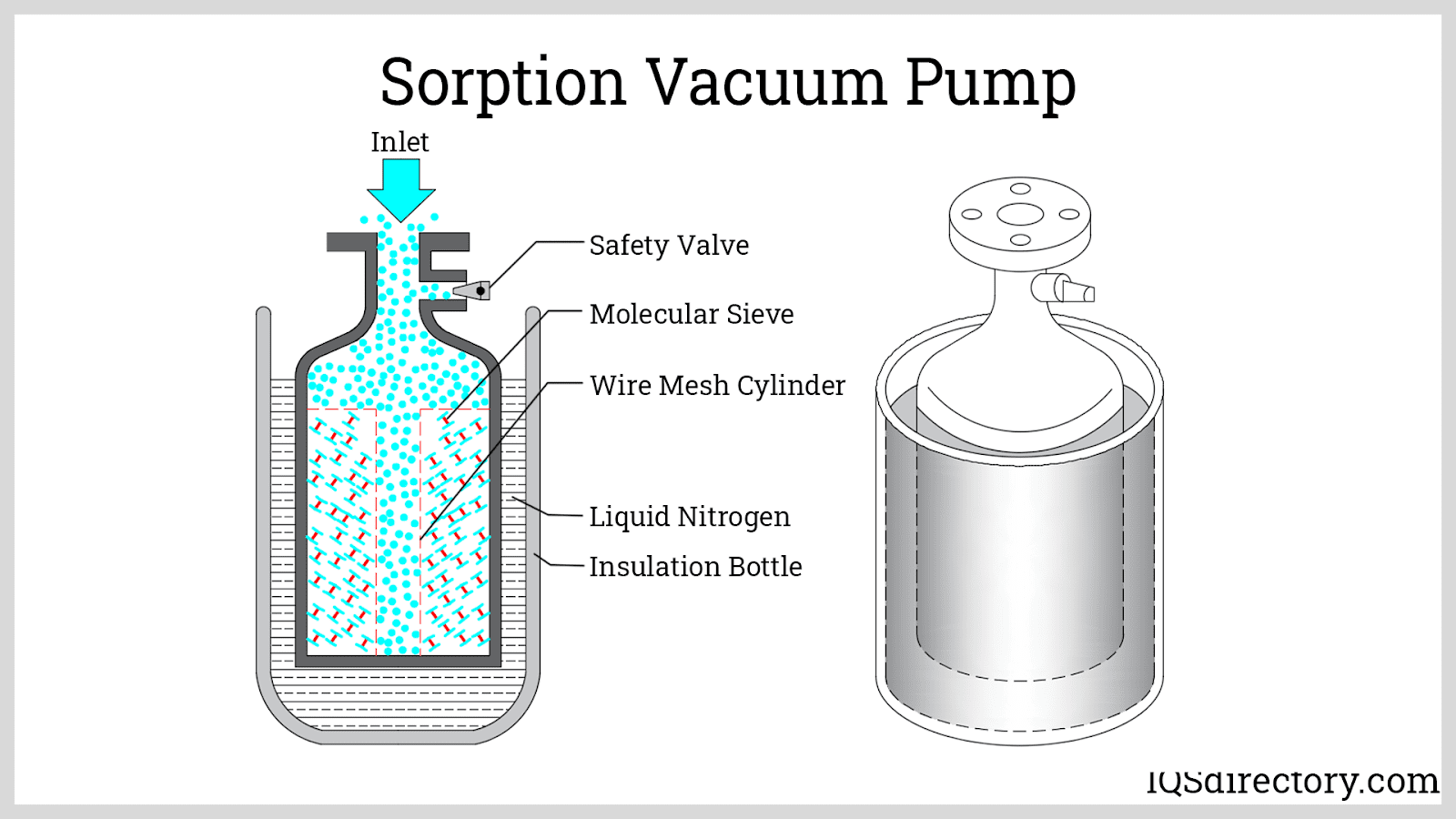

- Sorption Vacuum Pump: This type of pump uses adsorbents such every bit activated charcoal, zeolite, or other types of molecular sieves for capturing gas molecules. It is unremarkably paired with cryogenic pumps for condensing the gases or lowering the gas vapor pressure.

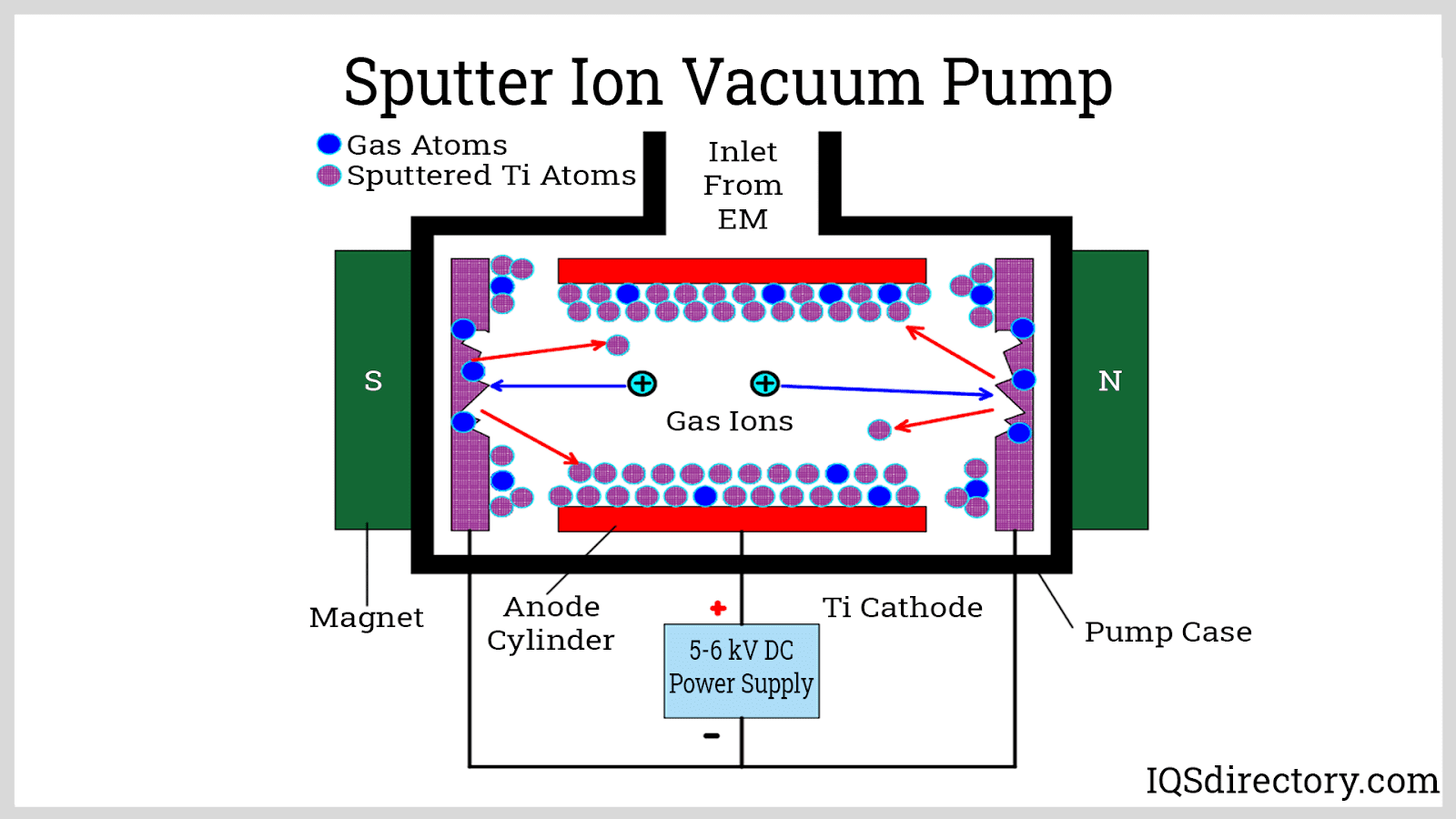

- Sputter Ion Vacuum Pump: Sputter ion vacuum pump, also known as ion getter pump or ion pump, operates by ionizing the incoming gases by an anode. The ionized gas so binds to a cathode or a getter, typically made of titanium. The binding may be through chemical or physical means depending on the type of gas present. As the ionized gas impacts the cathode, some atoms or electrons of the cathode are ejected from the surface, known every bit sputtering.

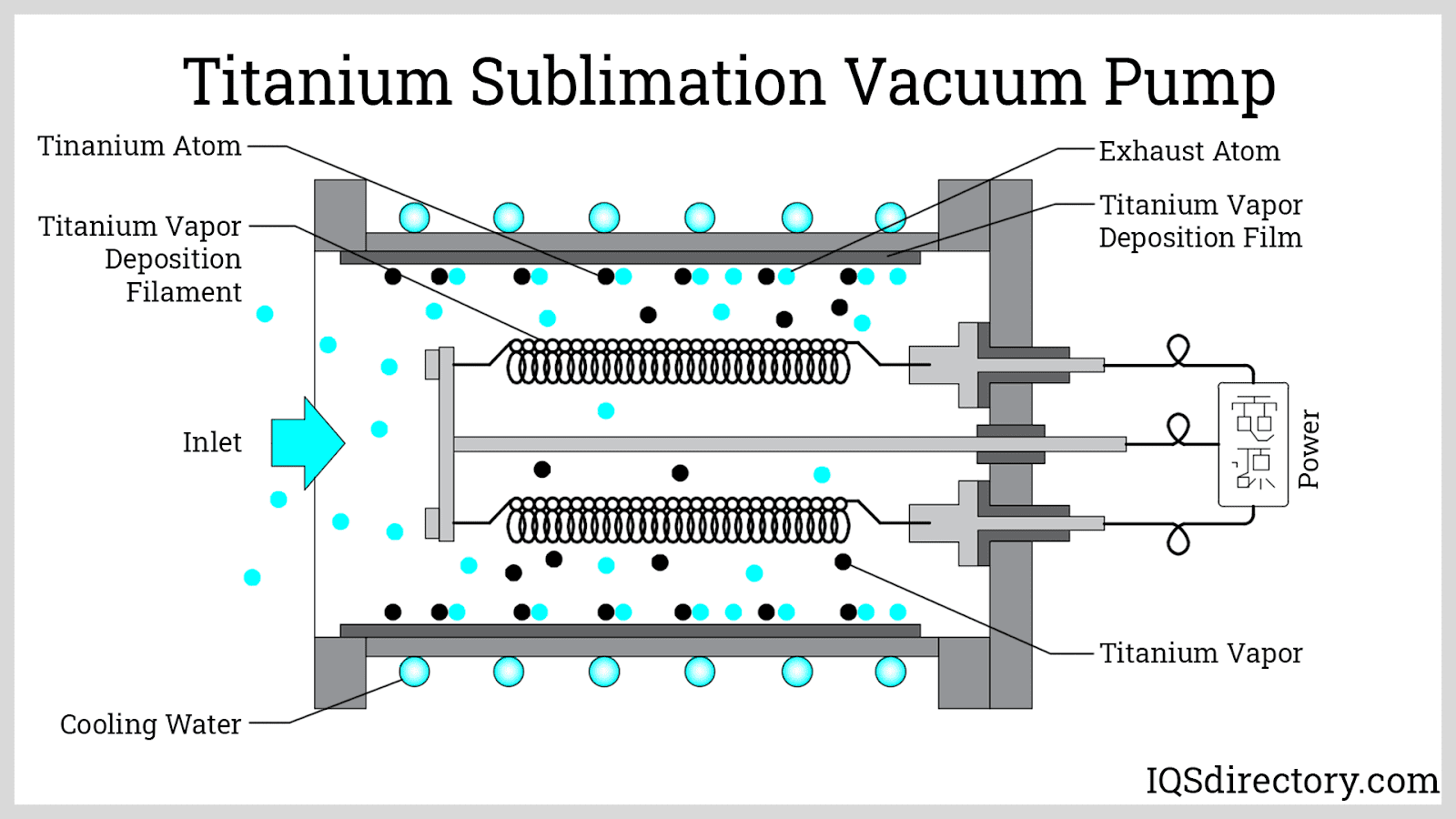

- Titanium Sublimation Vacuum Pump: In this blazon of vacuum pump, an electric current is periodically introduced through a titanium filament. This heats the titanium and directly vaporizes it inside a chamber. The gases flowing through or present in the chamber is captured by the vaporized titanium by bonding while in transit or upon developing a film on the chamber wall. In one case the titanium moving-picture show is consumed, the remaining titanium filament is again vaporized to create another layer.

Chapter 4: Wet and Dry Vacuum Pumps

Aside from the pumping principles, vacuum pumps can be categorized according to the blazon of lubrication and sealing system. Vacuum pumps tin be wet or dry lubricated. Choosing between the two mainly affects other performance factors such as wear resistance, pumping speed, fluid contamination, and so on.

- Wet Vacuum Pumps: In contrast with dry vacuum pumps, moisture vacuum pumps are generally cheaper. The chief lubricating fluid used is oil. Dissimilar types of oil are used depending on the awarding. Oil is supplied to the pump past an auxiliary lubricating system that performs boosted functions such every bit oestrus rejection and contaminant filtration. The downside of using moisture systems is the contact of oil with the fluid. An oil separator is used downstream to separate the oil from the gas.

- Dry Vacuum Pumps: These types of pumps do not accept a lubrication system. Rather, these pumps employ dry or solid lubricants such equally graphite, PTFE, and molybdenum disulfide. These materials have a low coefficient of friction and forestall the coated mating surfaces to be in metal-to-metal contact. Water cooling jackets lined along the pump housing are used to remove heat from the system. The master reward of dry systems is the contaminant-costless pumping. Moreover, they require less maintenance than wet vacuum pumps.

Affiliate v: Vacuum Ejectors

A vacuum ejector is a blazon of vacuum pump that operates using the Venturi effect. Within the vacuum ejector is a venturi which is frequently called a jet nozzle or orifice. The venturi has a cross-section that narrows into a smaller area and then gradually expands to the cross-section of the belch pipe. Connected immediately after the venturi is another stream of fluid. This is the vacuum connection.

The Venturi effect is based on Bernoulli'due south principle. This physical concept is basically the law of conservation of energy practical to fluids. Information technology states the inverse human relationship of kinetic energy and pressure: when a fluid's velocity increases, its pressure level decreases, and vice versa.

A motive fluid is used to create the Venturi effect. The motive fluid initially has a college pressure level which is converted into velocity as it passes the venturi. The high-speed jet of the motive fluid has a lower force per unit area which creates a vacuum in the surrounding regions. Vacuum is produced to any connection made on the depression-pressure regions.

A vacuum ejector has two main advantages.

- It has no moving parts: At that place are no reciprocating or rotating parts inside a vacuum ejector, different other vacuum pumps. It is just equanimous of a static venturi tube. This structure increases the reliability of the device and requires lilliputian to no maintenance.

- It uses waste product free energy from loftier-pressure sources: Vacuum ejectors are used when at that place is a steady source of high-pressure fluid such every bit steam, water, and effluent gas. Typically, these high-pressure lines are discharged into the atmosphere which wastes its potential energy. Loftier-pressure fluid is used as the motive fluid that drives the vacuum ejector.

On the other hand, the disadvantage of using a vacuum ejector is the inevitable mixing of the motive fluid and the fluid from the vacuum connection. If the intention is to recover the fluid drawn from the evacuated chamber, special separation techniques must be performed.

Vacuum ejectors are usually used in applications for drawing liquids such as h2o and steam where mixing the motive and vacuum streams poses no negative issues. They are commonly seen in power plants, petroleum and petrochemical plants, and water treatment facilities.

Determination:

- A vacuum pump is a piece of equipment capable of generating a partial vacuum or a low-pressure level space past drawing gas molecules out of a sealed bedchamber.

- A vacuum is a relative land at which the sleeping accommodation pressure has a lower pressure than the ambient atmosphere or adjacent systems.

- Vacuum ranges or regimes are classifications of the quality of vacuum characterized past the measurement of the absolute pressure of the system.

- The two main classifications of vacuum pumping principles are gas transfer and entrapment. Gas transfer is further divided into positive deportation and momentum transfer.

- Vacuum pumps can as well exist categorized according to the type of lubrication and sealing organisation. Vacuum pumps can exist wet or dry lubricated.

Become YOUR Company LISTED Below

Leading Manufacturers and Suppliers

Source: https://www.iqsdirectory.com/articles/vacuum-pump.html